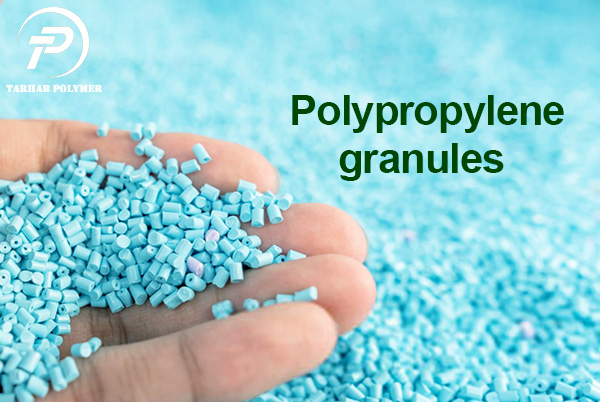

Tarh Ab Polymer company, with over 7 years of experience in the plastic recycling industry, is one of the top producers of recycled granules in Iran. This company is located in the Kahrizak area of Tehran and produces more than 15 tons of recycled granules daily with four equipped production lines.

Tarh Ab Polymer Leading Producer of Recycled Granules

Why Choose Tarh Ab Polymer?

✅Certified Quality: Our PP granules were approved by Fiat Italy in 2018

✅Trusted by Automotive Industries: Our company’s products are approved by compounders and parts manufacturers of Iran Khodro and SAIPA.

✅Custom Production: We produce polypropylene and polyethylene granules according to customer needs.

✅Equipped Laboratory: We are equipped with a complete polymer laboratory with precise GOTECH machines to ensure product quality.

✅Diverse Customers: We have customers ranging from automotive industries to toy manufacturers and construction equipment producers.

✅International Presence: We export products to CIS countries, the Persian Gulf region, European Union, Turkey, Iraq, and Pakistan.

At Tarh Ab Polymer, we are committed to providing high-quality and environmentally friendly products. By choosing us, you not only benefit from a product with high standards but also contribute to environmental preservation.

What are Recycled Granules?

Recycled granules are plastic pellets obtained from recycling used plastics and plastic waste. This product can replace raw materials in the production of new plastic products and plays an important role in reducing environmental pollution and reusing resources. Recycled granules come in various types, each with specific applications in different industries.

Variety of Tarh Ab Polymer Granules

Production of Various Types of Polypropylene (PP) Granules

♻️PP Copolymer granules are produced from recycling products such as buckets, chairs, and auto parts.

Used in the automotive and home appliance industries. This type of polymer is exported from our company to Iraq and Pakistan.

♻️PP Homopolymer granules are produced from recycling products such as buckets, chairs, and auto parts with high MFI. Used in the automotive industry.

♻️Recycled PP granules according to the datasheet provided by the customer with a new formula

Production of Various Types of Polystyrene (PS) Granules

♻️ High Impact Polystyrene (HIPS) is produced from recycling disposable containers and foam packaging. These types of granules are exported by Tarh Ab Polymer to Russia and Iraq.

♻️General Purpose Polystyrene (GPPS) is produced from recycling disposable containers and foam packaging. These types of granules are exported by Tarh Ab Polymer to Russia and Iraq.

Production of Various Types of Polyethylene (PE) Granules

♻️LDPE granules: Blow molding polyethylene with a grade equivalent to 0035. This type of polymer is exported from our company to Iraq and Caspian Sea region countries.

♻️HDPE granules: Injection molding polyethylene with grades similar to 62n07 and 52518.

This type of polymer is exported from Tarh Ab Polymer to Iraq and Caspian Sea region countries.

♻️HDPE granules: Extrusion polyethylene with a grade equivalent to PE100.

This type of polymer is exported from Tarh Ab Polymer to Iraq and Caspian Sea region countries.

Production of Various ABS Granules and Compound Granules

♻️ABS granules in various colors, produced from recycling electronic components and home appliances.

♻️Compound granules are produced from several recycled materials according to customer data with a new formula.

Tarh Ab Polymer Knowledge Base

Here you can familiarize yourself with the latest articles in the polymer industry.

Recycled Granules, Polypropylene, and Polyethylene

Polypropylene (PP) and Polyethylene (PE) granules are two widely used polymers in the plastic and rubber industry. Both have long lifespans, high quality, and flexibility.

Polypropylene is more suitable for applications that require higher thermal and chemical resistance. Meanwhile, polyethylene is ideal for products that need more flexibility.

The choice between recycled granules, polypropylene, and polyethylene depends on the specific needs of your project. Considering environmental, economic, and quality factors, you can select the best option for your application.

What are the differences between these granules?

Resistance

- Polypropylene: Harder and more resistant to fatigue, better resistance to solvents and chemicals

- Polyethylene: Softer and more flexible against fatigue, good resistance, but less against solvents and chemicals

Transparency

- Polypropylene: Greater transparency

- Polyethylene: Usually more opaque

Quality and Purity

- Recycled granules: May have impurities and variable quality

- Polyethylene: High purity and uniform quality

Cost

- Recycled granules: Usually cheaper

- Polyethylene: Higher price

Environmental Impact

- Recycled granules: Environmentally friendly and helps reduce plastic waste

- Polyethylene: Its production requires extraction of new resources

Production Origin

- Recycled granules: Produced from used plastic products.

- Polyethylene: Made directly from petroleum materials.

Molecular Structure

- Polypropylene: More organized molecular chains

- Polyethylene: More branched molecular structure

Applications

- Recycled granules: Suitable for products requiring medium quality.

- Polyethylene: Used for high-quality and sensitive products such as bottles, plastic bags, pipes.

- Polypropylene: Suitable for food containers, automotive parts, medical equipment.

Density

- Polypropylene: Lower density (about 0.9 g/cm³)

- Polyethylene: Higher density (between 0.91 to 0.97 g/cm³)

Thermal Resistance

- Polypropylene: Higher melting point (around 160°C)

- Polyethylene: Lower melting point (between 115 to 135°C)